Parts of the Plastic Injection Molding Modality

The process of injection molding is applied to get the thin-walled fabricated part of the plastic for a vast variability of the plastic applications. The process of the plastic injection molding is implemented by the manufacturers to make the products of plastic that are considered as the basic necessities of the daily routine, for instance, toothbrushes, combs, crockery and many other.

The process includes simple instrumentation of the plastic injection molding parts through which the raw material (thermoplastic resin beans) are heated to get molten by a melting machine, an injection to inject the molten plastic and mold or a furnace to provide the base of shaping to the end product.

The process of injection molding heats the polymer to the point where it gets liquid enough and reflects plastic properties and its elasticity reaches to highest points so that the process of molding could be done smoothly.

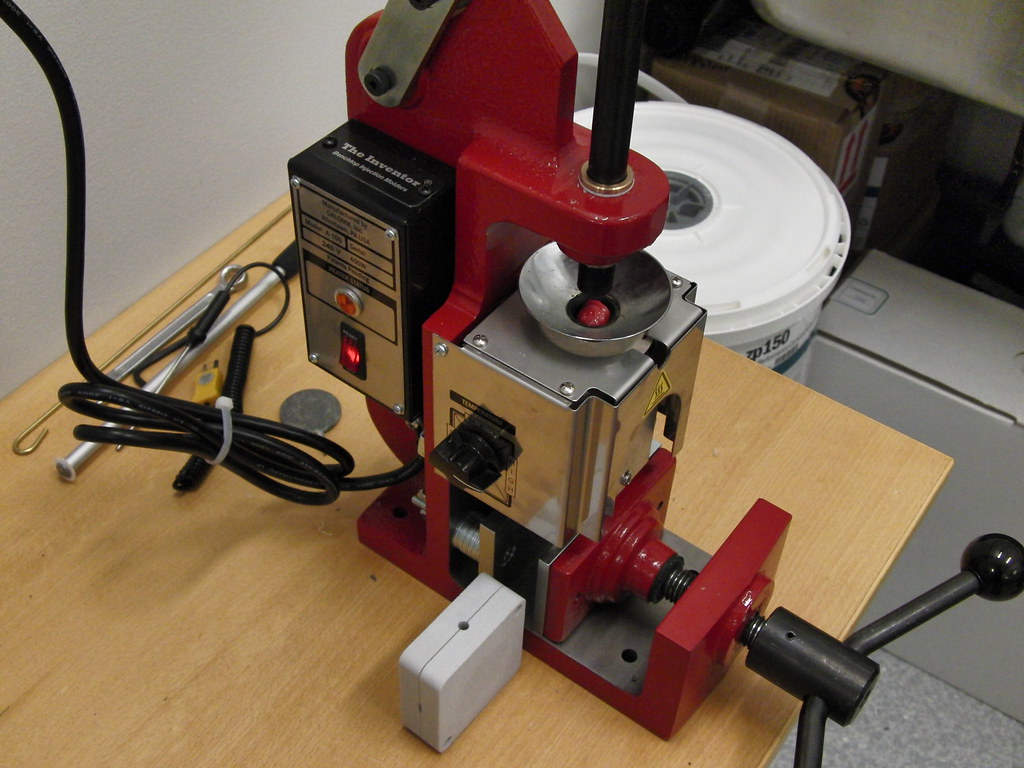

Plastic injection molding is conventionally divided into two parts which include, a unit for the plastic injection and a unit for the mold clamping. Both of these units work separately, yet has interconnected targets to achieve. The functions of both the parts of plastic injection molding require respective handling.

Plastic Injection Unit

This is the first step to the process that is a target to get the raw plastic beans into a molten lava form so that the injecting could be done. The core objective of the injection unit is to homogenize the melted plastic prior to its injection in the cavity of the mold. The injection of the component resembles an extruder. The structure encompasses a barre, a screw that rotates to heat-up the raw polymer to melt it. The screw pushes down the molten plastic into the injection and also prevents its backflow. After that, the molding cycle places the molten cycle in molds for shaping the material.

Mold Clamping Unit

The clamping unit holds up the molds into the positions through which the injected material got spread evenly into furnaces. This structure has holding clamps to perform the task of fixation of the parts thru reasonable amount of forces.